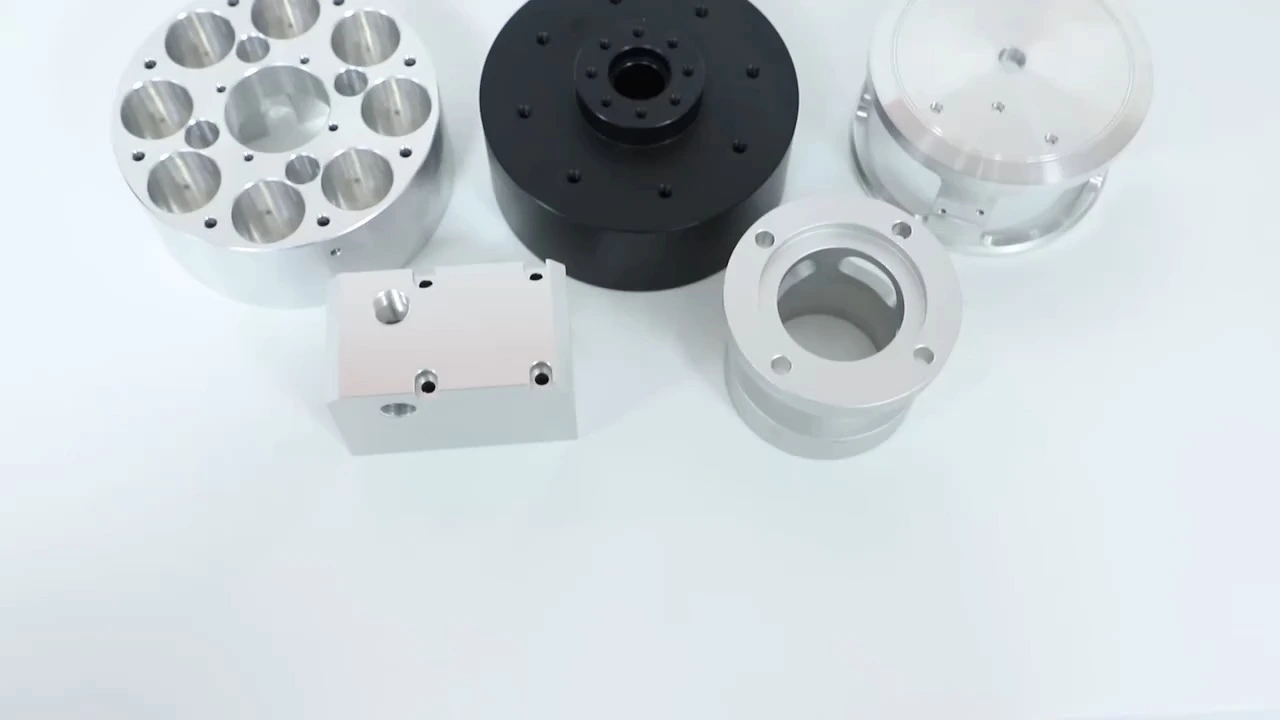

China Factory CNC Manufacturer High Precision Spare Parts Car Custom Cnc Parts Central Machinery Car Engine Parts

Types of Gears: There are several types of gears, including spur gears, which have straight teeth and are used for parallel shafts; bevel gears, which are used to change the axis of rotation; and worm gears, which provide high torque and are often used in gear reduction applications. Each type serves specific functions based on the design and application requirements.

Material and Manufacturing: Gears can be constructed from various materials, such as steel, aluminum, and plastic, depending on the application’s strength and weight requirements. They are typically manufactured through processes like machining, forging, or injection molding, ensuring precision and durability.

Applications and Importance: Gears are found in countless applications, from everyday items like bicycles and clocks to complex machinery in automotive and aerospace industries. Their ability to efficiently transfer power and control speed makes them vital components in ensuring the smooth operation of mechanical systems.

High-precision stainless steel CNC parts

Stainless steel precision machining parts designed for medical, food and marine engineering support rapid prototyping and mass production of complex structural parts. Using 5-axis linkage CNC center and Swiss precision lathe, it achieves the ultimate processing capability of minimum hole diameter 0.2mm and wall thickness 0.3mm, and provides 18 surface treatment solutions such as passivation, electrolytic polishing, PVD coating, etc., meeting the stringent standards of FDA, ASTM and NACE.

ISO 9001/AS9100 certified | ±0.01mm tolerance | Fully compatible with 304/316/17-4PH materials

Product Details

Product Advantages

Technical advantages

Material advantages

Service Advantages

Application

FAQ

If you have any questions, please feel free to contact us at ada@honscn.com or by phone at +86 17722440307