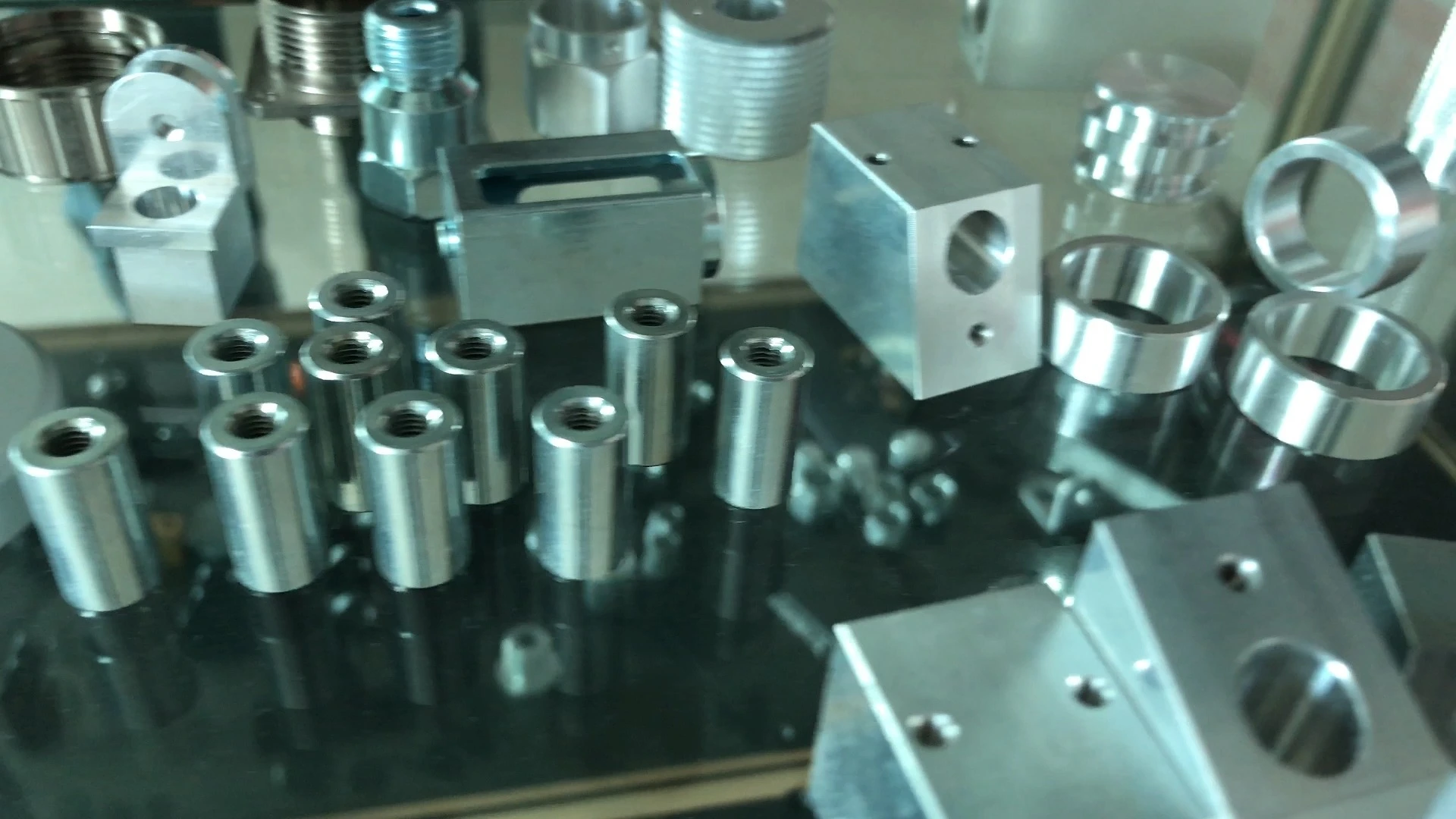

Custom Non-Standard Cnc Machining Parts

The advantages of non-standard customized CNC parts include:

1. High Precision:CNC machines can achieve micron-level accuracy, ensuring consistent dimensions and shapes.

2.High Quality

- Surface Finish: Produces smooth surfaces, reducing the need for additional finishing processes.

- Strict Quality Control: Ensures each part meets standards through rigorous quality inspections.

3.Cost-Effectiveness

- Reduced Waste: Precision machining minimizes material waste.

- Lower Labor Costs: Automated production reduces labor costs.

4.Wide Applications

- Cross-Industry Use: Applicable in industries such as aerospace, automotive, medical, and electronics.

- Versatility: Meets diverse needs from prototyping to final product manufacturing.

5.Customization Flexibility

- Personalized Design: Tailored to meet specific customer requirements, suitable for unique applications.

- Quick Adjustments: Rapid design modifications through programming to adapt to different needs.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Please fill out the form below to request a quote or to request more information about us. please be as detailed as possible in your message, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave a message

Feel free to contact with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Contact Us

Contact: Ada Li

Tel: +86 17722440307

WhatsApp: +86 17722440307

E-mail: vicky@honscn.com

Add: 4F, No. 41 Huangdang Road, Luowuwei Industrial, Dalang Street, Longhua, Shenzhen, 518109, China

Copyright © 2025 HONSCN |Sitemap Privacy Policy

Contact us

Leave your inquiry, we will provide you with quality products and services!

Contact us

email

Contact customer service

Contact us

email

cancel

Customer service