Aluminium Cnc Machining Parts Stainless Steel Wholesale - HONSCN

Product Overview

- High-precision stainless steel CNC parts designed for medical, food, and marine engineering applications

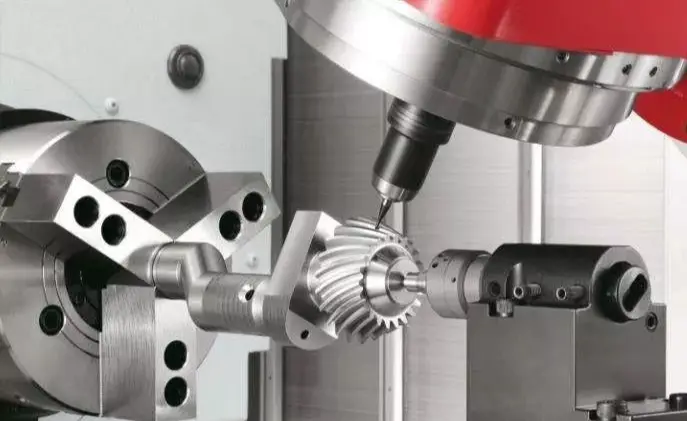

- Processed using 5-axis CNC centers and Swiss precision lathes

- Surface treatments such as passivation, electrolytic polishing, and PVD coating are available

- Certified with ISO 9001/AS9100 and can work with materials like 304/316/17-4PH

Product Features

- Maximum size of 800×500×400mm (expandable to 1500mm)

- Tolerance grade of ±0.05mm for conventional parts and ±0.01mm for precision parts

- Surface roughness from Ra 0.4μm to Ra 3.2μm

- Post-processing options include electrolytic polishing, chemical passivation, and titanium nitride coating

Product Value

- Customized solutions from design to production based on customer needs

- After-sales service with 24-hour technical support and global logistics support

- Materials like 304 stainless steel for general purpose corrosion resistance and 17-4PH stainless steel for precipitation hardening

Product Advantages

- Ultra-precision machining with 5-axis CNC synchronous accuracy

- Ultimate machining capabilities for micro-hole drilling and deep cavity milling

- Multi-process integrated machining in one clamping for improved accuracy and efficiency

Application Scenarios

- High-end manufacturing such as semiconductor wafer fixtures and vacuum chamber components

- Marine engineering for desalination pump impellers and subsea valve components

- Consumer electronics like reactor stirring paddles and oil and gas pipeline flanges

- Industrial automation including robot joint arms, linear module sliders, and visual inspection brackets