Bulk Aluminium Cnc Machining Parts Manufacturer

Product Overview

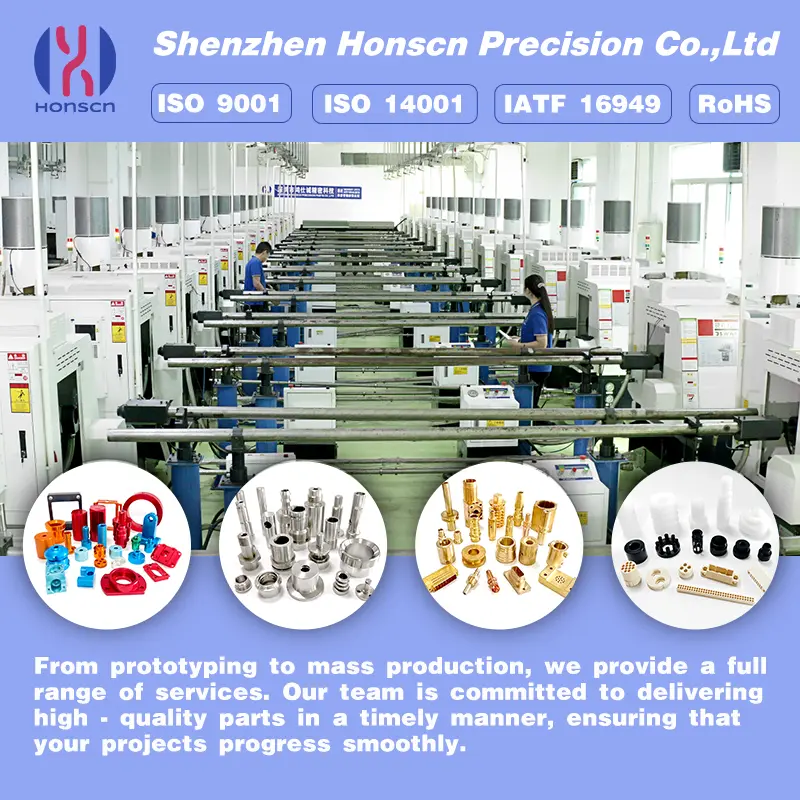

- The Bulk Aluminium CNC Machining Parts are high-quality parts sourced from top-grade suppliers.

- The parts have a wide range of applications and can be used in various fields such as aerospace, automotive, and consumer electronics.

- The product is designed for rapid prototyping and mass production of complex structural parts using a 5-axis machining center.

Product Features

- High-precision CNC aluminum parts with a minimum hole diameter of 0.5mm and a wall thickness of 0.3mm.

- Surface treatment solutions include hard anodizing, micro-arc oxidation, and sandblasting matte for lightweight and high strength.

- ISO 9001/AS9100 certified with ±0.02mm tolerance and 6061/7075/5083 aluminum material options.

Product Value

- The product offers ultimate machining capabilities and composite processing technology to improve processing accuracy and production efficiency.

- Material options include 6061-T6 for general-purpose structural parts, 7075-T651 with strength comparable to steel, and 5083-H32 for seawater corrosion resistance.

Product Advantages

- Technical advantages include ultra-precision machining, deep cavity milling, micro-hole machining, and composite processing technology.

- Material advantages include high tensile strength and corrosion resistance.

- Service advantages include customized solutions, after-sales support, and global logistics.

Application Scenarios

- Aerospace: UAV fuselage frame, satellite bracket, aviation engine fuel nozzle.

- New energy vehicles: Battery tray structural parts, electric drive housing, charging gun interface.

- Consumer electronics: Mobile phone middle frame, AR glasses frame, heat sink fins.

- Industrial automation: Robot joint arm, linear module slider, visual inspection bracket.