Cnc Aluminum Parts CNC Aluminum Parts Wholesale - HONSCN

Product Overview

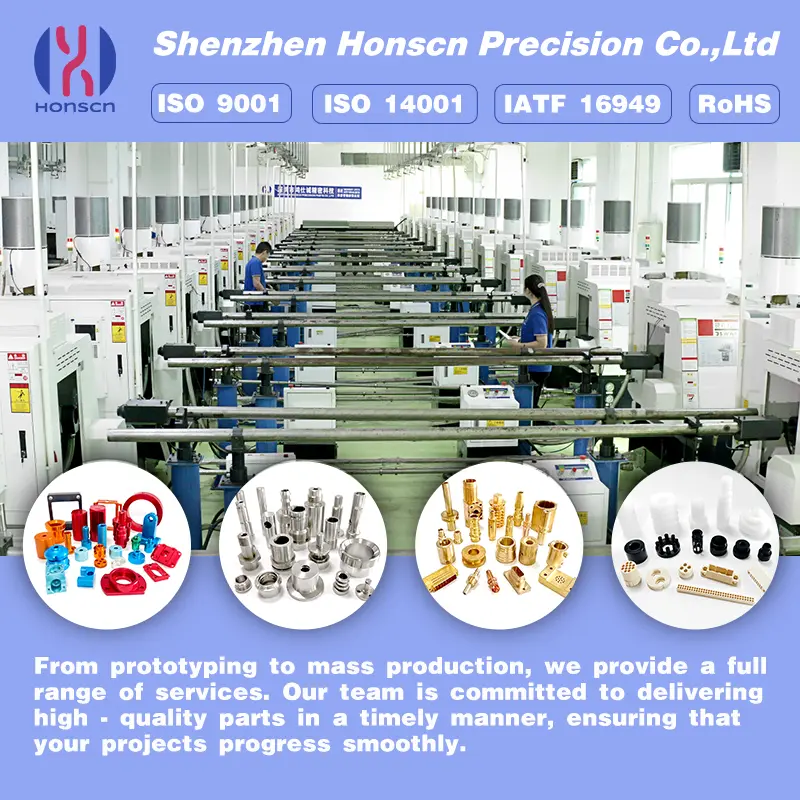

Honscn Co.,Ltd offers high-precision CNC aluminum parts designed for aerospace, automotive, and consumer electronics industries. The product features precision machining for rapid prototyping and mass production of complex structural parts.

Product Features

The CNC aluminum parts are processed using a 5-axis machining center, achieving ultimate processing capabilities with a minimum hole diameter of 0.5mm and a wall thickness of 0.3mm. The product provides 15 surface treatment solutions such as hard anodizing and micro-arc oxidation to meet lightweight and high strength requirements.

Product Value

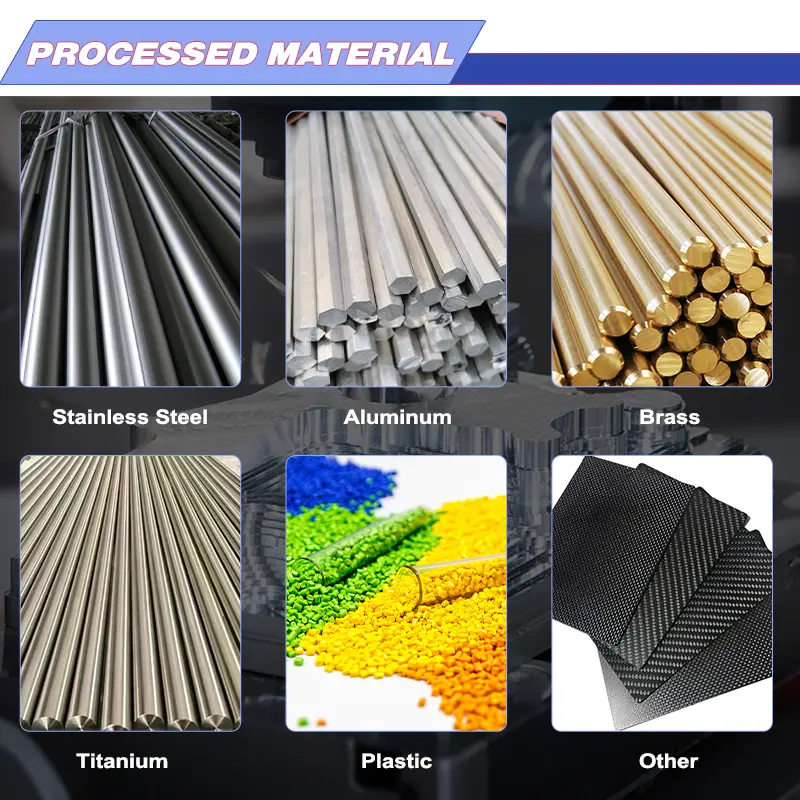

Honscn Co.,Ltd's CNC aluminum parts are ISO 9001/AS9100 certified, ensuring high quality and precision. With materials like 6061, 7075, and 5083 aluminum available, the product offers a wide range of options for different applications.

Product Advantages

The technical advantages of the CNC aluminum parts include ultra-precision machining, composite processing technology, and material advantages like high tensile strength and corrosion resistance. The service advantages include customized solutions, after-sales support, and global logistics for efficient delivery.

Application Scenarios

The CNC aluminum parts are used in aerospace, new energy vehicles, consumer electronics, and industrial automation industries for applications such as UAV fuselage frames, battery tray structural parts, mobile phone frames, robot joint arms, and more. The product is versatile and adaptable to various manufacturing needs.