Cnc Parts - - HONSCN

Product Overview

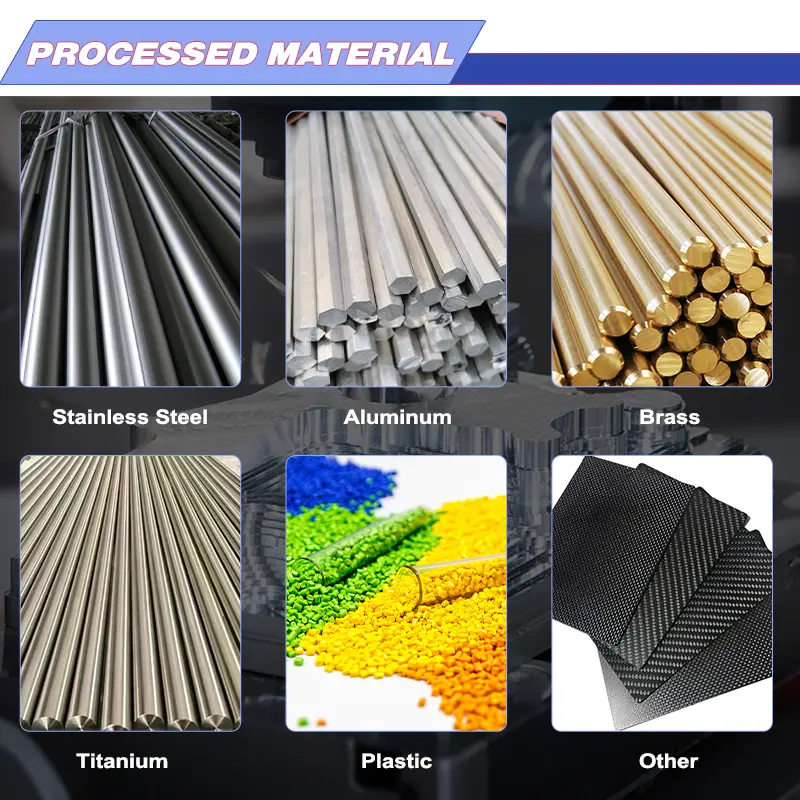

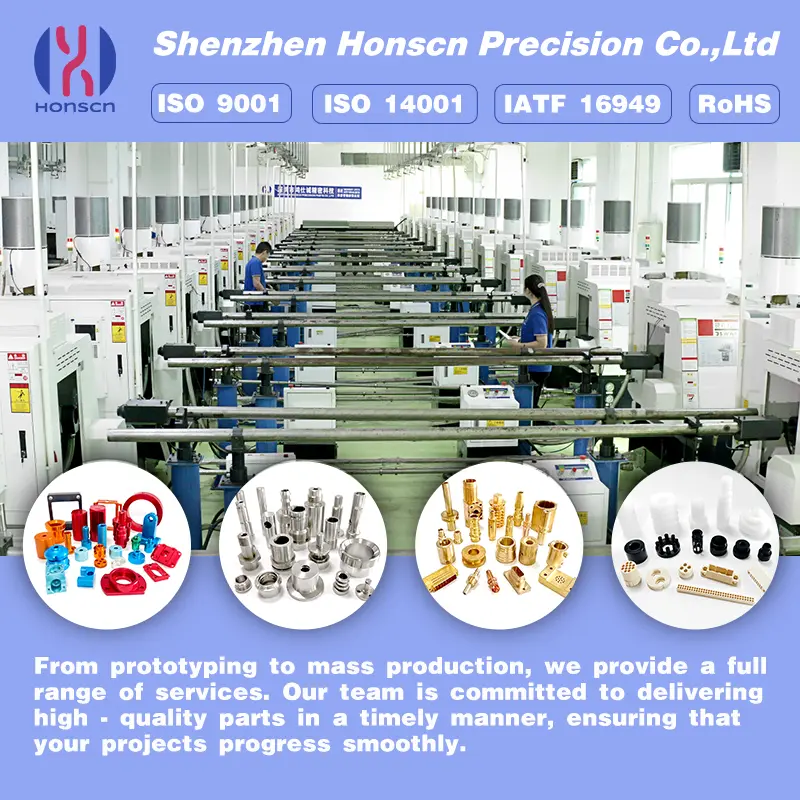

The product is high-precision stainless steel CNC parts designed for medical, food, and marine engineering. It utilizes 5-axis CNC center and Swiss precision lathe for rapid prototyping and mass production of complex structural parts. It meets the stringent standards of FDA, ASTM, and NACE.

Product Features

The product has a maximum processing range of 800×500×400mm (expandable to 1500mm) with tolerance grades of ±0.05mm for conventional parts and ±0.01mm for precision parts. It offers 18 surface treatment solutions such as passivation, electrolytic polishing, and PVD coating. The product is fully compatible with 304/316/17-4PH materials.

Product Value

The product offers technical advantages such as ultra-precision machining, ultimate machining capabilities, and multi-process integrated machining. It also provides material advantages including corrosion resistance and precipitation hardening. Customized services, after-sales support, and global logistics are additional value-added services offered.

Product Advantages

The product has technical advantages of ultra-precision machining, multi-process integrated machining capabilities, and material advantages of corrosion resistance and high tensile strength. Customized services, after-sales support, and global logistics enhance the overall advantages of the product.

Application Scenarios

The product is suitable for high-end manufacturing, marine engineering, consumer electronics, and industrial automation applications. It can be used in semiconductor wafer fixtures, marine components, consumer electronics parts, and industrial automation components. The product offers versatility and precision for various application scenarios.