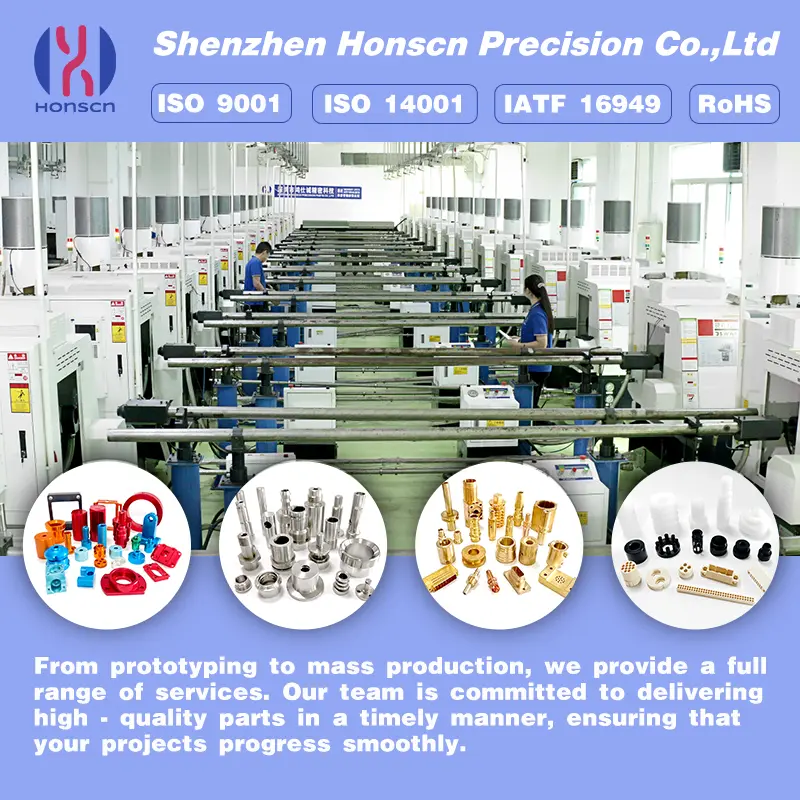

HONSCN High Precision Custom Gears Price List

Product Overview

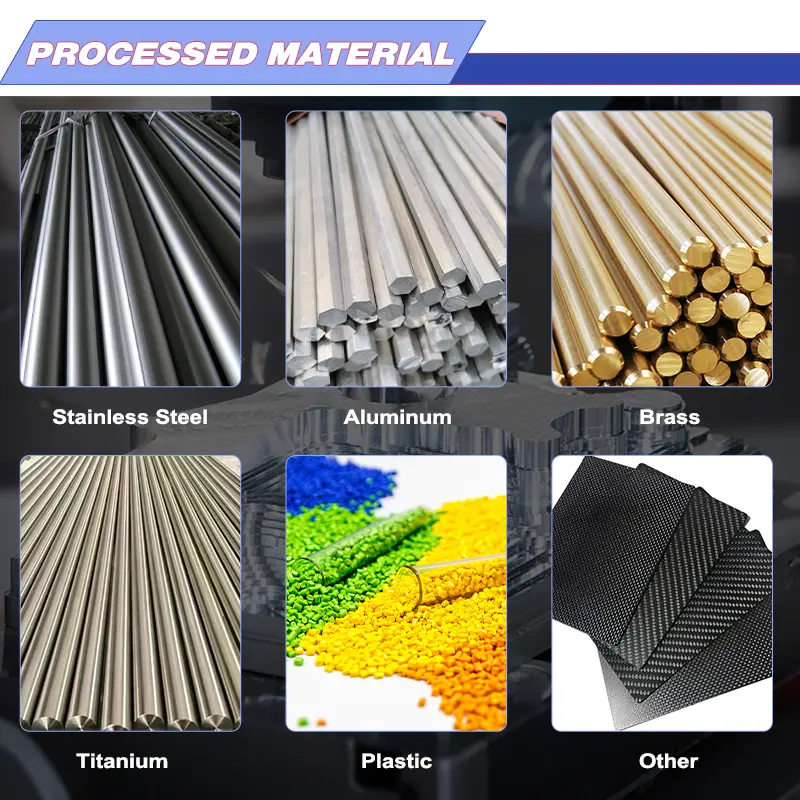

HONSCN High Precision Custom Gears offers high-precision spur gears designed for industrial equipment, automotive transmission, and automation systems. Made of AISI 4340 alloy steel, POM engineering plastics, and aluminum bronze.

Product Features

Full parameter customization with module 0.5-20 and number of teeth 10-200. Transmission efficiency ≥ 98% and working life over 10,000 hours. Certified by DIN/AGMA with surface hardening HRC60+.

Product Value

The product meets international quality standards with high-performance advantages such as ultra-high strength, ultra-low wear, and precision meshing. Material advantages include steel, plastic, and copper alloy gears.

Product Advantages

Advanced processing technology with a five-axis machining center for precise processing. Fine heat treatment with vacuum quenching and tempering process for improved gear performance.

Application Scenarios

Suitable for industrial machinery, automobile manufacturing, energy equipment, and medical equipment. Can be used in various applications like reducers, gearboxes, wind turbines, and MRI equipment.