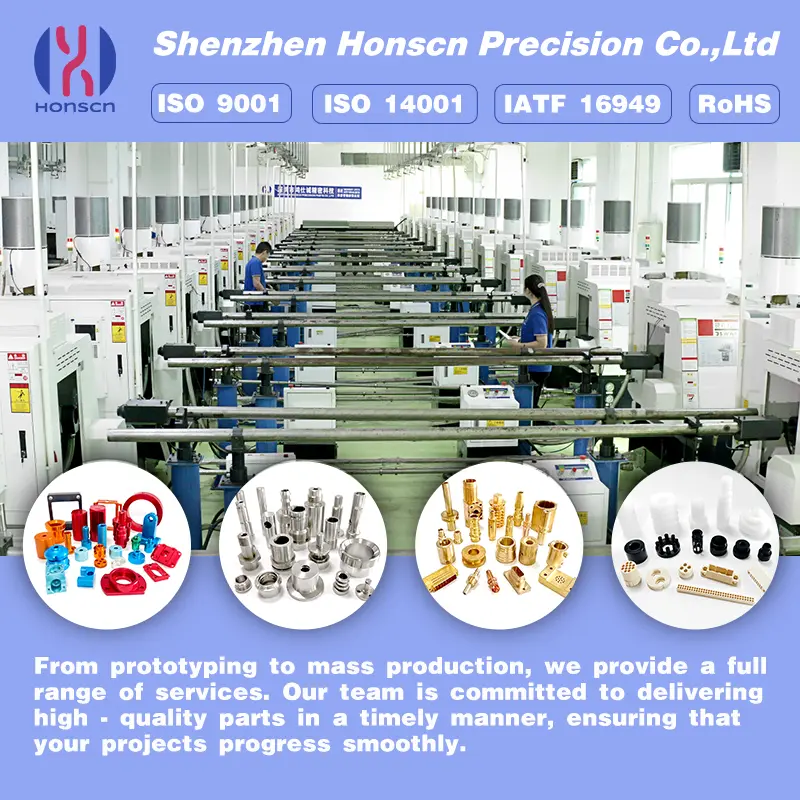

Stainless Steel Cnc Machining Parts Factory

Product Overview

The stainless steel CNC machining parts are designed to provide the best user experience and have brought economic benefits to customers. The product is expected to be widely used in the market with a wholly-owned sales subsidiary in many regions in China.

Product Features

High-precision stainless steel CNC parts designed for medical, food, and marine engineering. Utilizes 5-axis linkage CNC center and Swiss precision lathe for ultimate processing capabilities. Offers 18 surface treatment solutions meeting FDA, ASTM, and NACE standards.

Product Value

ISO 9001/AS9100 certified with ±0.01mm tolerance. Fully compatible with 304/316/17-4PH materials. Ultra-precision machining with micro-hole drilling and deep cavity milling capabilities.

Product Advantages

Technical advantages include multi-process integrated machining, material advantages with different stainless steel options, customized service from design to production, and after-sales service with 24-hour online support.

Application Scenarios

Suitable for high-end manufacturing, marine engineering, consumer electronics, and industrial automation. Applications include semiconductor wafer fixtures, desalination pump impellers, reactor stirring paddles, and robot joints.