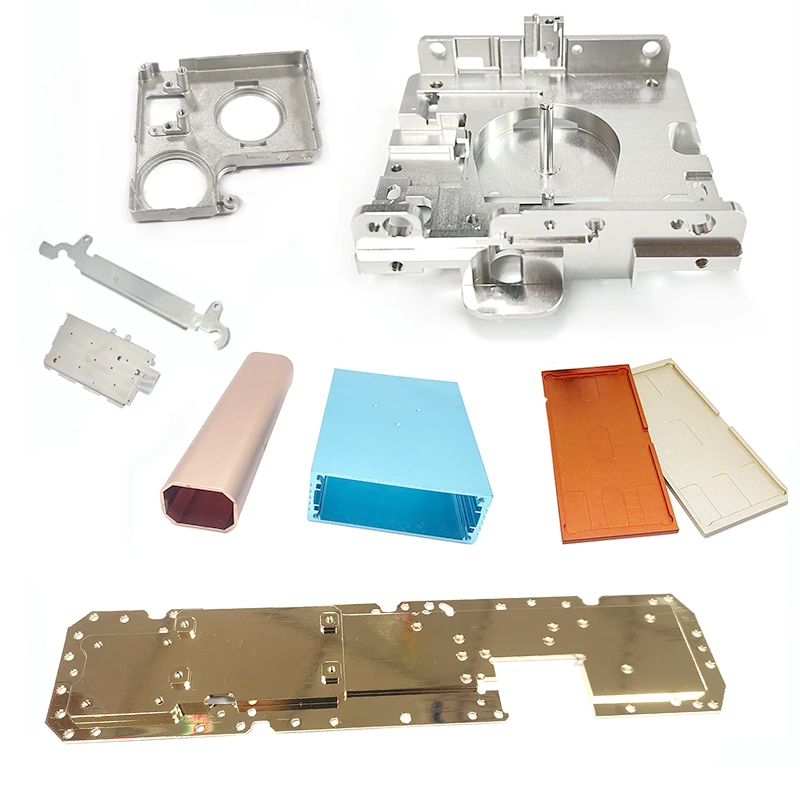

Customized precision sheet metal parts | Rapid prototyping | One-stop processing of multiple materials

Core functions: Customize sheet metal parts with complex geometric structures to meet functional requirements such as equipment housings, brackets, radiators, etc.

Core advantages: Fully automatic laser cutting (±0.05mm accuracy) + intelligent bending compensation algorithm + traceless surface treatment

Key details: Support 20 surface processes such as powder coating/anodizing/brushed polishing, optional EMI shielding coating

User value: Reduce comprehensive manufacturing costs by 35%, accelerate product iteration, and comply with RoHS/REACH environmental standards

Differentiation highlights: Transparent production + 99% delivery accuracy

Customized precision sheet metal parts

High-precision sheet metal processing services for industrial equipment, electronic housings and architectural decorations, supporting stainless steel (304/316), aluminum (5052/6061), galvanized steel and copper alloy materials, with thicknesses of 0.5mm-12mm. Integrating laser cutting, CNC bending, stamping and welding processes, it achieves full-process delivery from design verification to 10,000-level mass production, shortening the cycle by 60% compared to the traditional model.

ISO 9001 certification | ±0.1mm tolerance | Full process coverage of laser cutting/bending/welding

Product Details

Product Advantage

Technical advantages

Quality Advantage

Delivery Advantages

Application

FAQ

If you have any questions, please feel free to contact us at ada@honscn.com or by phone at +86 17722440307