Custom Sheet Metal Fabrication Price List

Product Overview

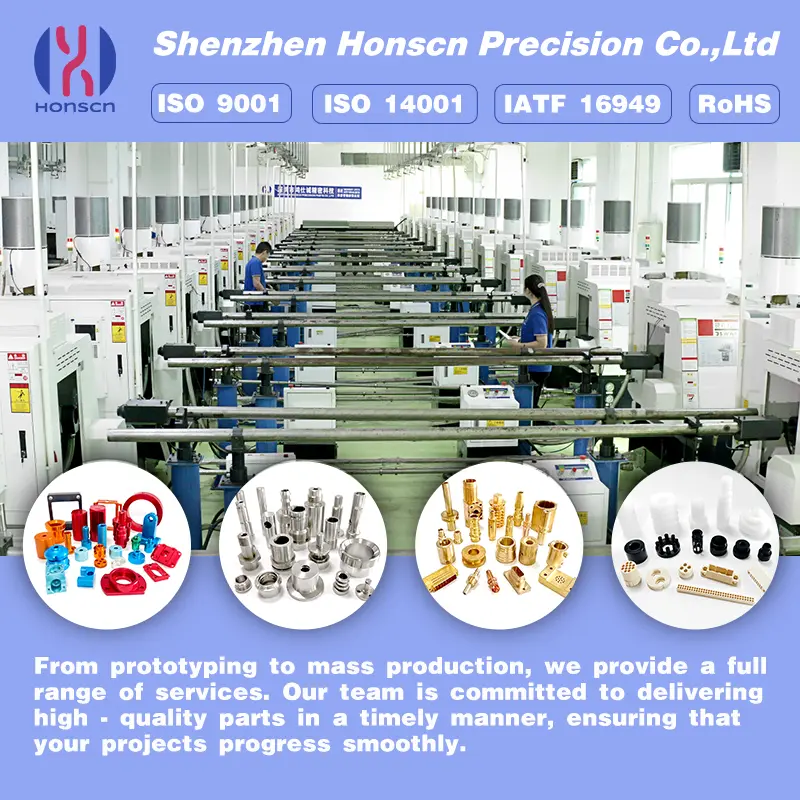

- Custom Sheet Metal Fabrication offered by HONSCN, with precision sheet metal parts for various applications

- Utilizes high-quality materials such as stainless steel, aluminum, and copper alloy, with thickness range of 0.5mm-12mm

- ISO 9001 certified with full process coverage of laser cutting, bending, and welding

Product Features

- High-precision processing with 6kW fiber laser cutting machine

- Flexible production supporting small batch customization

- Quality control measures include advanced testing equipment and high-quality raw materials

- Various surface treatments available such as electrostatic spraying and anodizing

- Efficient production processes with regular orders delivered within 7-10 days

Product Value

- Guaranteed authenticity and quality of custom sheet metal fabrication

- ISO 9001 certification ensures compliance and quality standards

Product Advantages

- Technical advantages include ultra-precision processing and process integration

- Quality advantage with high-precision testing and high-quality raw materials

- Delivery advantages with efficient production and logistics guarantee

Application Scenarios

- Industrial equipment such as control cabinet housing and sensor mounting bracket

- Consumer electronics including server chassis and drone structural parts

- Automobile manufacturing for battery tray sheet metal and vehicle display frame

- Medical equipment like surgical instrument tray and MRI equipment shielding cover