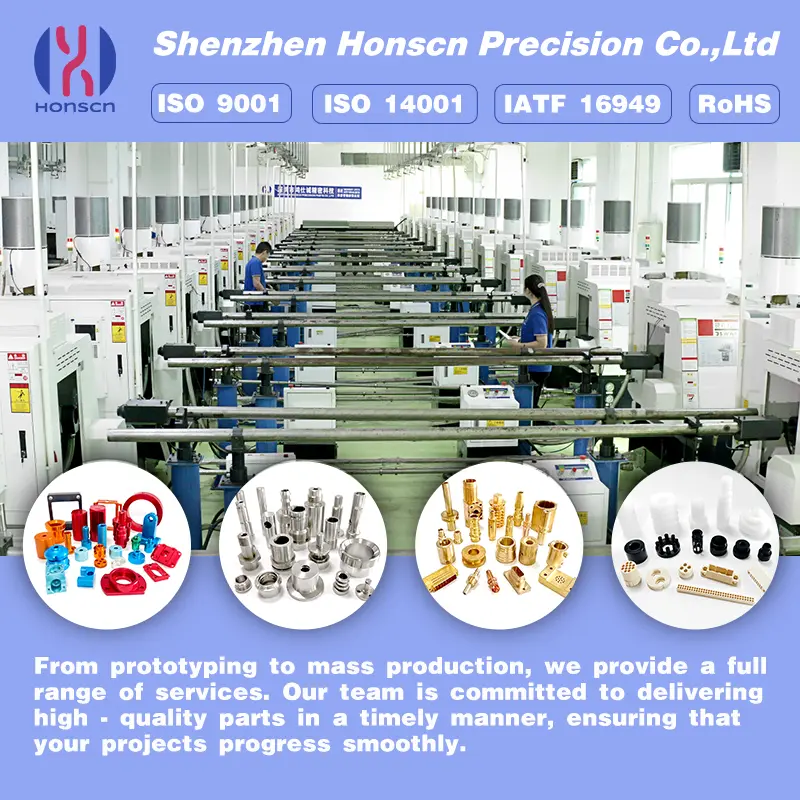

Factory Price Custom Sheet Metal Fabrication Custom Sheet Metal Fabrication Company

Product Overview

- Customized precision sheet metal parts made from materials such as stainless steel, aluminum, and brass

- Utilizes laser cutting, CNC bending, stamping, and welding processes

- Offers full-process delivery from design verification to mass production

Product Features

- Material options include cold rolled steel, stainless steel, aluminum, and brass

- Tolerances of ±0.1mm for laser cutting and ±0.5° for bending

- Various surface treatments available such as sandblasting oxidation and electrophoretic coating

Product Value

- ISO 9001 certification and compliance with industry standards

- High-precision testing equipment for accurate dimensions

- Flexible production capabilities for small batch customization

Product Advantages

- Ultra-precision processing with a 6kW fiber laser cutting machine

- Quality raw materials and strict supplier cooperation

- Process integration for reduced supply chain links

Application Scenarios

- Industrial equipment such as control cabinet housing and conveyor rails

- Consumer electronics including server chassis and smart home panels

- Automobile manufacturing for battery trays and charging pile housings

- Medical equipment like surgical instrument trays and MRI shielding covers