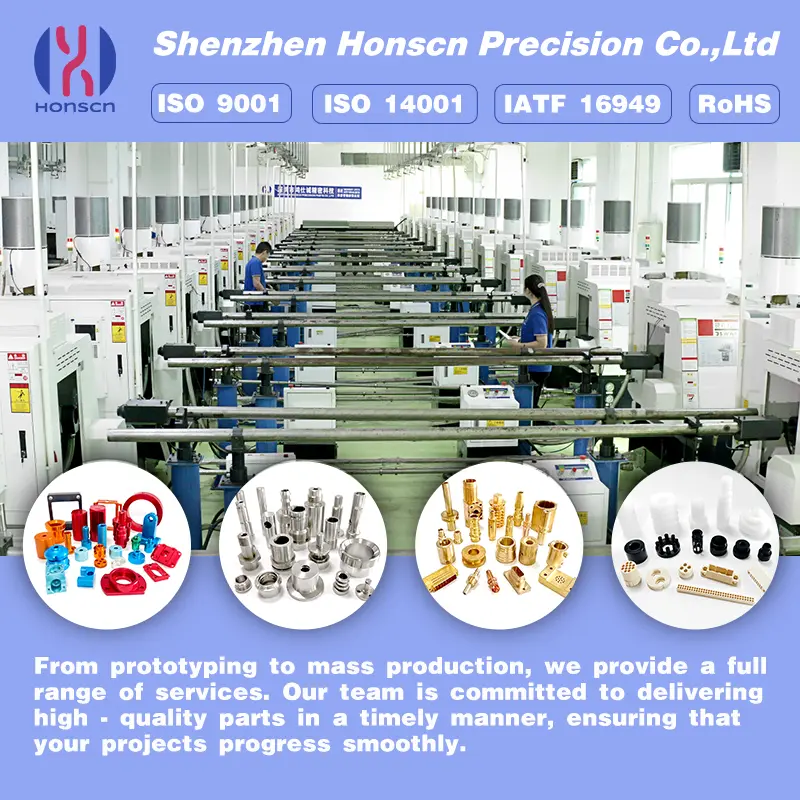

HONSCN Planetary Gearbox Suppliers China Manufacturer

Product Overview

- HONSCN Planetary Gearbox Suppliers China Manufacturer offers high-precision spur gears designed for industrial equipment, automotive transmission, and automation systems.

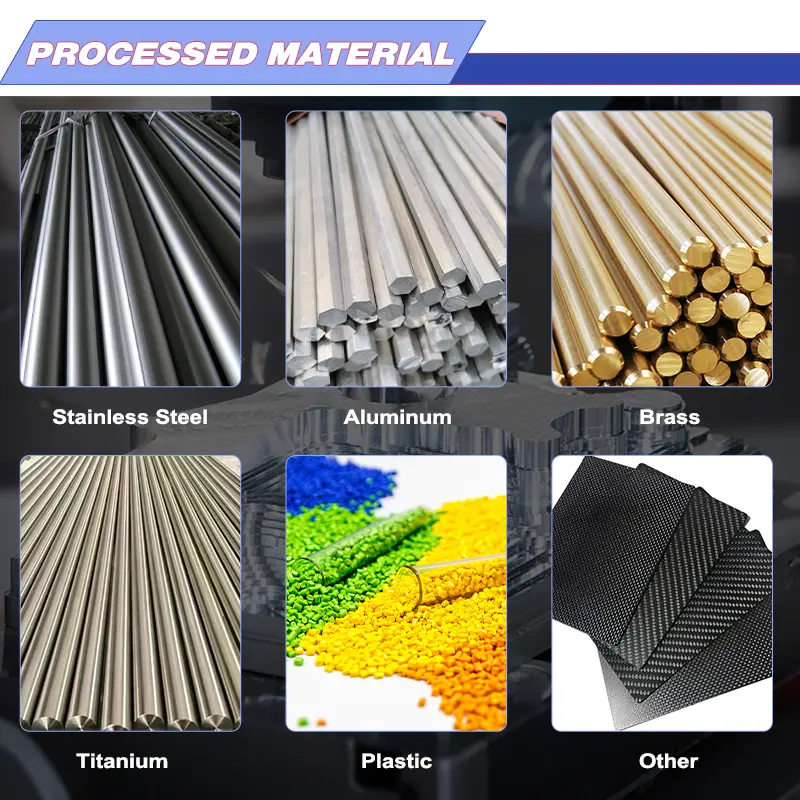

- The product is made of AISI 4340 alloy steel, POM engineering plastics, and aluminum bronze, with transmission efficiency of ≥ 98% and a working life of over 10,000 hours.

Product Features

- Modulus range of 0.5-20 with pressure angle options of 20° (standard)/14.5°/25° and tooth width range of 5mm-200mm.

- Heat treatment processes include carburizing and quenching, high-frequency induction hardening, and vacuum nitriding.

- Material advantages include steel gear for impact resistance, plastic gear for self-lubrication, and copper alloy gear for corrosion resistance.

Product Value

- High performance advantages with ultra-high strength, ultra-low wear, and precision meshing.

- Advanced production processes using five-axis machining center and fine heat treatment.

Product Advantages

- Alloy steel bending strength ≥1500MPa and surface hardness HRC60-64.

- Steel gears resistant to impact loads, plastic gears self-lubricating, and copper alloy gears resistant to seawater corrosion.

- Products certified under DIN 3960 Class 3, AGMA 2001-C95, ISO 1328-1 standards.

Application Scenarios

- Industrial machinery for reducer power transmission gears, packaging machine indexing mechanisms, and CNC machine tool spindle boxes.

- Automobile manufacturing for gearbox synchronous gears, electric window lifters, and hybrid system power distribution mechanisms.

- Energy equipment for wind turbine yaw gears, oil rig transmission boxes, and nuclear power plant cooling pump drive gears.

- Medical equipment for MRI equipment rotation drive gears and surgical robot joint transmissions.