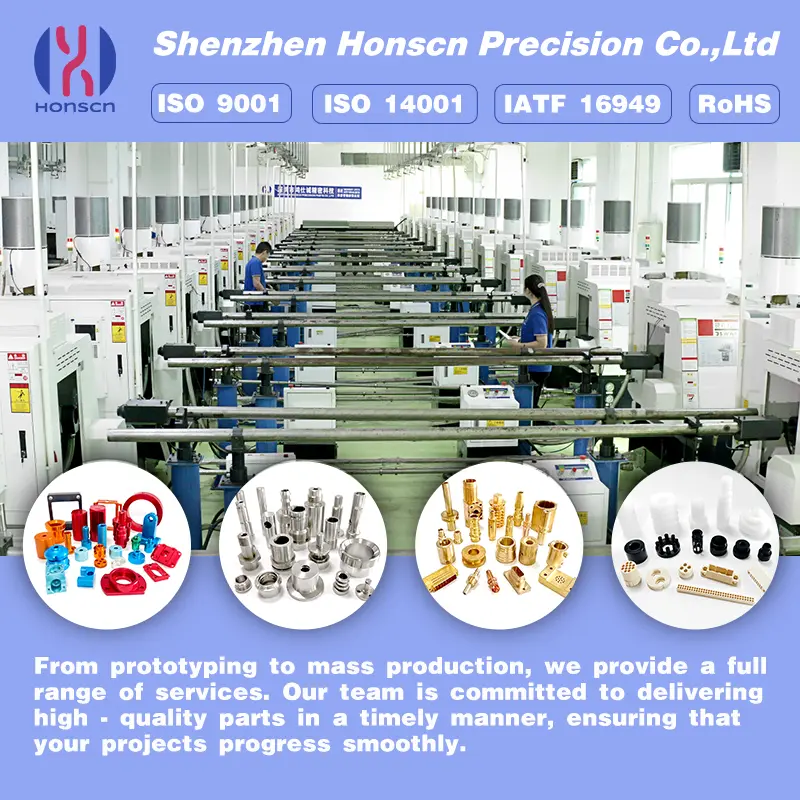

HONSCN Precision Cnc Milling Parts Company

Product Overview

- HONSCN Precision CNC Milling Parts Company specializes in customized CNC turning and milling parts designed for complex transmission systems, fluid control components, and precision instruments.

- The parts support 5-axis synchronous turning and milling and can achieve a surface finish of Ra0.4μm.

Product Features

- Material options include aluminum alloy, stainless steel, titanium alloy, PEEK, and PA66.

- Processing range includes maximum diameter Φ300mm, length ≤600mm, and load ≤200kg.

- Surface treatment options include micro-arc oxidation, chemical nickel plating, and mirror polishing.

Product Value

- ISO 9001 certification ensures high-quality standards.

- 72-hour rapid proofing allows for quick production.

- Fully compatible with aluminum, stainless steel, titanium alloy, and engineering plastics.

Product Advantages

- Technical advantages include high precision, versatility, and the ability to create complex designs.

- Process advantages include automation, quality control, and tool life extension.

- Service advantages include fast turnaround, customization, and comprehensive support services.

Application Scenarios

- Medical equipment, automobile manufacturing, energy equipment, and industrial robot applications are suitable for precision cnc milling parts.

- Specific examples include artificial joint femoral stems, turbocharger housings, nuclear-grade valve cores, and robotic arm connection flanges.