Laser Cut Sheet Metal Services Price List

Product Overview

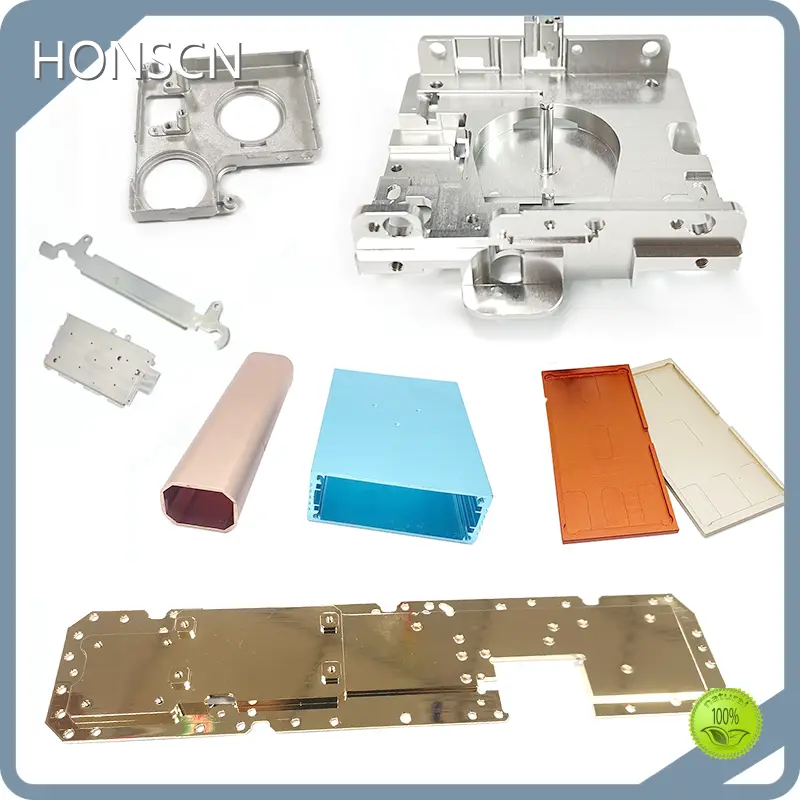

The Laser Cut Sheet Metal Services offered by HONSCN are customized precision sheet metal parts designed for use in industrial equipment, electronic housings, and architectural decorations. It integrates laser cutting, CNC bending, stamping, and welding processes to deliver high-quality products.

Product Features

The product offers material options such as cold rolled steel, stainless steel, aluminum, and brass, with thickness ranges and tolerance standards specified for laser cutting and CNC bending. Surface treatments include sandblasting oxidation, electrophoretic coating, and laser engraving QR codes. The product is compliant with ISO 9001 and IATF 16949 certifications.

Product Value

HONSCN's Laser Cut Sheet Metal Services provide customers with technical advantages such as ultra-precision processing, flexible production capabilities, and process integration. The product also offers quality advantages including high-precision testing, high-quality raw materials, and various surface treatment options. Efficient production and logistics guarantee timely delivery.

Product Advantages

The product's technical advantages lie in its ultra-precision processing capabilities, flexible production for small batch customization, and process integration reducing supply chain links. Quality advantages include high-precision testing, high-quality raw materials, and various surface treatments. Delivery advantages ensure efficient production and safe, fast delivery through collaboration with large logistics companies.

Application Scenarios

The Laser Cut Sheet Metal Services can be applied in various industries including industrial equipment for control cabinet housing and robot protective covers, consumer electronics for 5G base station heat sinks and server chassis, automobile manufacturing for battery tray sheet metal and charging pile housing, and medical equipment for surgical instrument trays and MRI equipment shielding covers. The product offers customization options and technical support for seamless bending, burr removal, and control of welding deformation.