Machined Plastic Parts CNC Machining Parts Wholesale - HONSCN-1

Product Overview

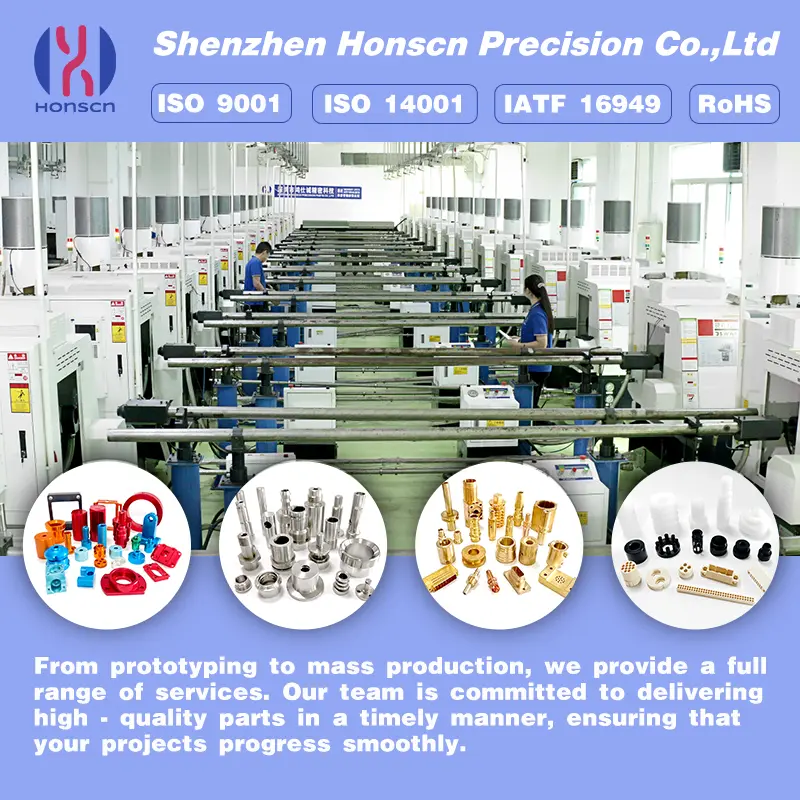

HONSCN offers high-quality machined plastic parts made of premium materials, with careful inspection and documentation before entering the market. The company provides factory prices for their products.

Product Features

Customized CNC turning parts designed for high-complexity turning parts for precision transmission systems, fluid control devices, and automation equipment. It supports turning and milling compound processing and can process 72 geometric features. Various materials and surface treatments are available.

Product Value

The product is ISO 9001/AS9100 certified with ±0.02mm tolerance. Material options include aluminum alloy, stainless steel, brass, and engineering plastics. Surface treatment options include hard anodizing, passivation, mirror polishing, and PTFE coating. Certifications include IATF 16949, ISO 13485, and ISO 9001.

Product Advantages

Technical advantages include ultra-precision machining, compound machining, multi-axis linkage, elastic clamping, high-pressure cooling, MQL, and cold extrusion compounding. Service advantages include drawing optimization, technical support, and customized services.

Application Scenarios

The product is suitable for various industries such as automobile manufacturing, aerospace, medical equipment, and energy equipment. Specific applications include turbocharger shaft, ABS valve body precision bushing, hydraulic actuator piston rod, minimally invasive surgical instrument sleeve, fuel cell bipolar plate flow channel, and more.

Overall, HONSCN's machined plastic parts offer high precision, technical advantages, and a wide range of applications, making them a valuable choice for industries requiring precision machining.