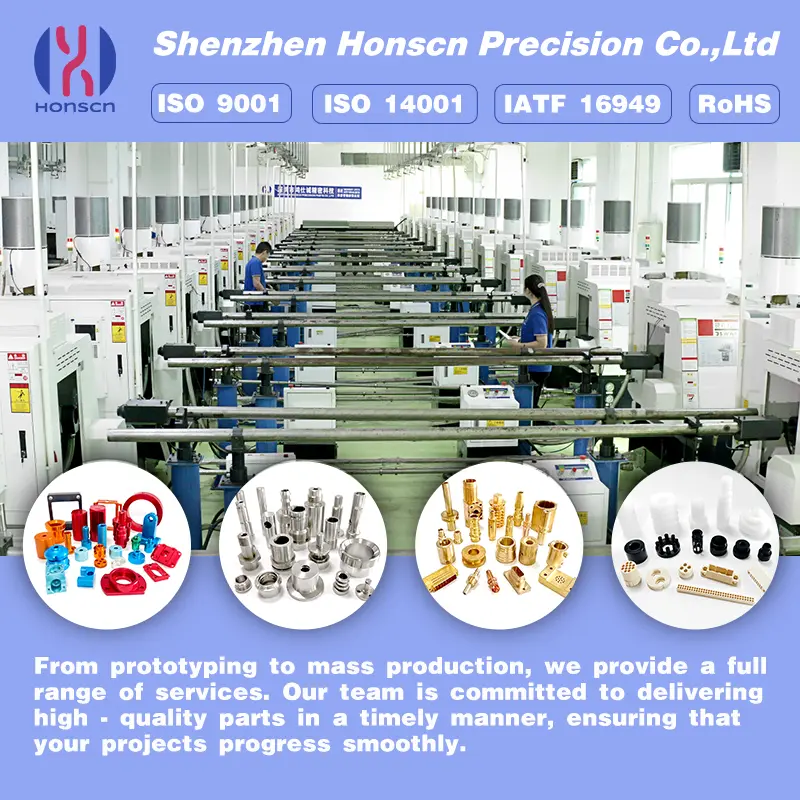

Planetary Gear Manufacturer Gear Wholesale - HONSCN

Product Overview

HONSCN Planetary Gear Manufacturer offers high-precision spur gears designed for industrial equipment, automotive transmission, and automation systems.

Product Features

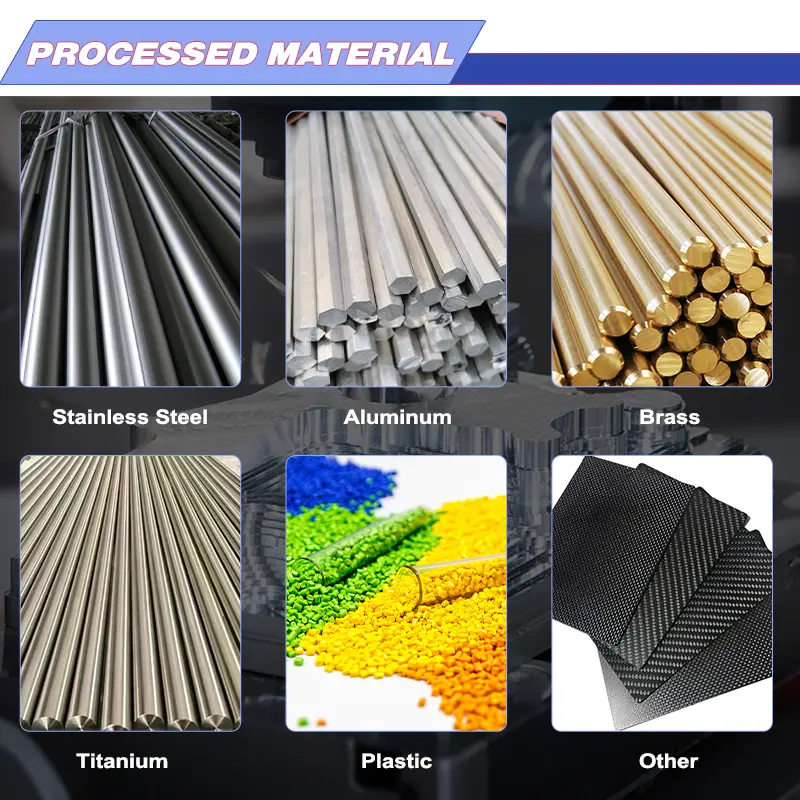

The gears support full parameter customization with a modulus range of 0.5-20 and a tooth width range of 5mm-200mm. They are made of AISI 4340 alloy steel, POM engineering plastics, and aluminum bronze, with high transmission efficiency and a working life of over 10,000 hours.

Product Value

Certified by DIN/AGMA standards, these gears offer ultra-high strength, ultra-low wear, and precision meshing. Material advantages include resistance to impact loads for steel gears, self-lubrication for plastic gears, and corrosion resistance for copper alloy gears.

Product Advantages

The gears are manufactured using advanced processing technology, such as CNC gear hobbing and carburizing. They undergo fine heat treatment processes like vacuum quenching and tempering to improve overall performance.

Application Scenarios

The gears find applications in industrial machinery, automobile manufacturing, energy equipment, and medical equipment. They are used in various systems such as reducer power transmission gear, wind turbine yaw gear, and MRI equipment rotation drive gear.