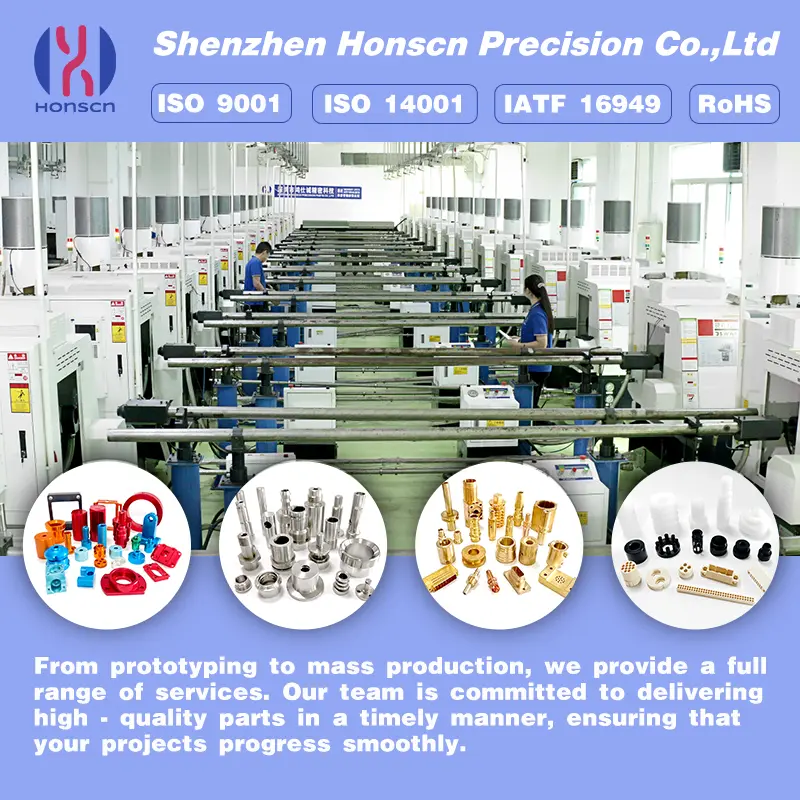

Wholesale Aluminum Cnc Part Price List

Product Overview

- The product is high-precision stainless steel CNC parts designed for medical, food, and marine engineering applications.

- It utilizes 5-axis CNC technology and Swiss precision lathe to achieve precise processing capabilities.

- The product is ISO 9001/AS9100 certified and fully compatible with materials such as 304, 316, and 17-4PH stainless steel.

Product Features

- Processing range of up to 800×500×400mm, expandable to 1500mm.

- Tolerance grade of ±0.05mm for conventional parts and ±0.01mm for precision parts.

- Surface roughness options include mirror polishing, fine milling, and rough machining.

- Post-processing options include electrolytic polishing, chemical passivation, and coating.

Product Value

- The product offers ultra-precision machining with 5-axis CNC synchronous accuracy of ±0.005mm.

- It provides ultimate machining capabilities including micro-hole drilling and deep cavity milling.

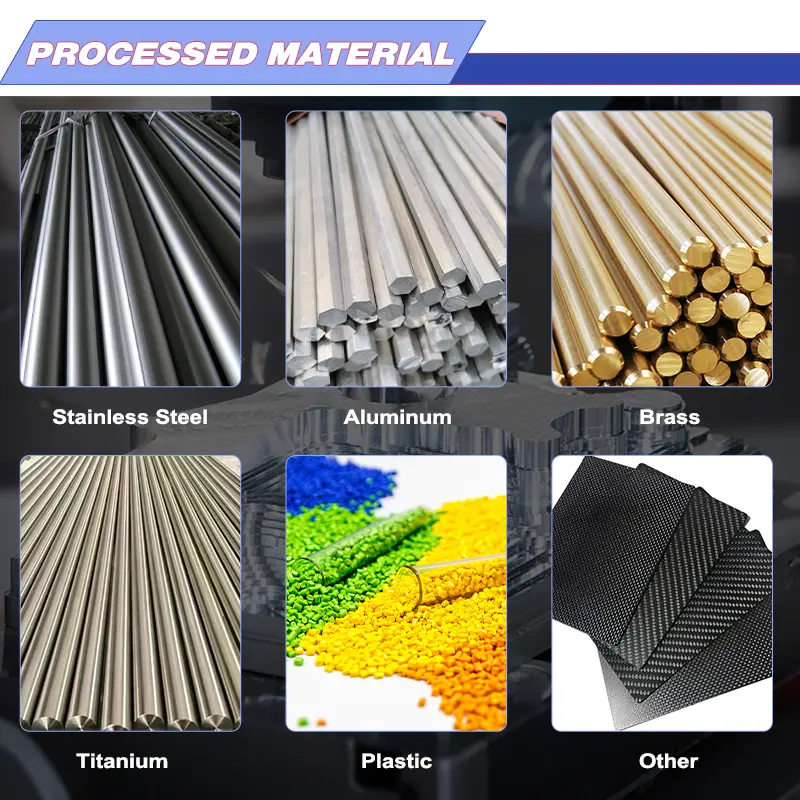

- The material options include 304 stainless steel for general purpose corrosion resistance, 316L stainless steel for chloride corrosion resistance, and 17-4PH stainless steel for precipitation hardening.

Product Advantages

- Technical advantages include multi-process integrated machining and reduced clamping errors.

- Material advantages ensure suitability for various applications in high-end manufacturing, marine engineering, consumer electronics, and industrial automation.

- Customized service and after-sales support are provided to meet customer needs.

Application Scenarios

- High-end manufacturing: semiconductor wafer fixtures, vacuum chamber components.

- Marine engineering: desalination pump impellers, subsea valve components.

- Consumer electronics: reactor stirring paddles, oil and gas pipeline flanges.

- Industrial automation: robot joint arm, linear module slider, visual inspection bracket.