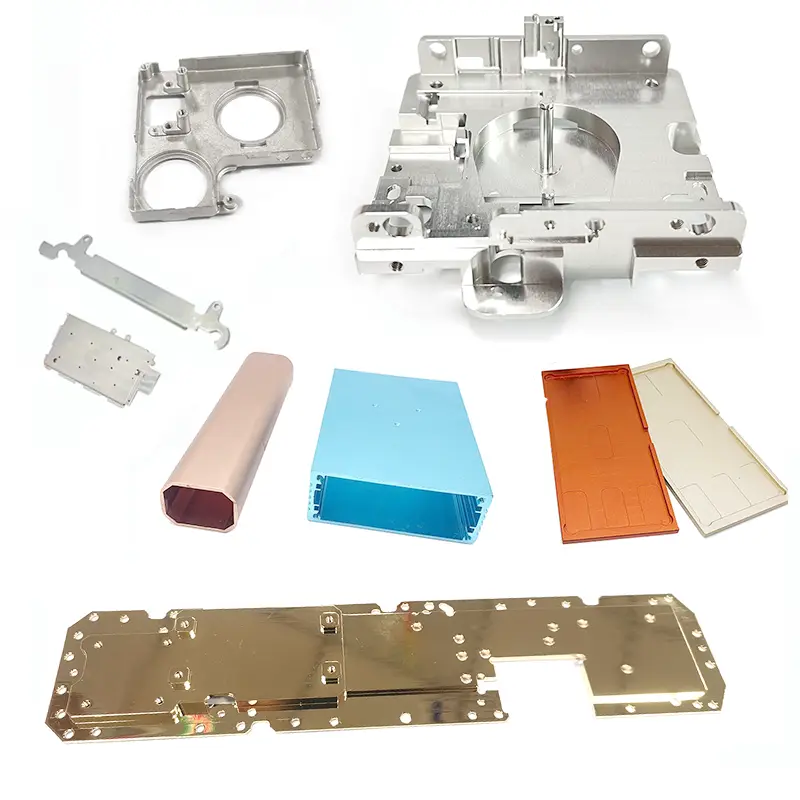

Automotive Metal Stamping Parts Series

automotive metal stamping parts is known for optimal quality. The raw materials are the foundation of the product. Honscn Co.,Ltd has established a complete set of standards for selecting and testing raw materials to ensure that the product is always made of qualified materials. The well-controlled production process also contributes to improving quality. All production procedures have been implemented according to top international standards.

automotive metal stamping parts is vital for Honscn Co.,Ltd to achieve business success. Cast by raw materials which meet the quality standards, it is featured by a high degree of stability and long-term durability. In order to meet international standards for quality, preliminary tests are repeatedly implemented. The product gains more recognition from the customers by its stable performance.

Automotive metal stamping parts are precision-engineered components formed through specialized manufacturing processes. These parts are crucial for structural support and functional performance in vehicles, while also enhancing aesthetic finishes. The production ensures high repeatability and accuracy, adhering to strict industry standards.

- Automotive metal stamping parts are crafted from high-strength materials like steel or aluminum alloys, ensuring long-term resistance to wear and corrosion in demanding environments.

- Ideal for under-the-hood components, structural reinforcements, and exterior panels where durability is critical.

- Look for parts with anti-corrosion coatings or heat-treated surfaces for enhanced longevity in extreme conditions.

- Utilizing advanced CNC stamping technology, these parts meet tight tolerances (±0.01mm) for seamless integration into complex automotive systems.

- Suitable for engine components, transmission parts, and sensor housings requiring exact dimensional accuracy.

- Verify compatibility with OEM specifications and request quality certifications (e.g., ISO/TS 16949) for precision assurance.

- Available in customizable shapes and sizes, these parts support diverse applications such as chassis frames, brackets, and body panels for various vehicle models.

- Applicable across electric vehicles, traditional combustion engines, and hybrid systems for both structural and functional roles.

- Opt for manufacturers offering rapid prototyping and multi-material options (steel, aluminum, titanium) to meet specific design needs.

**The Role of CNC Machining in Automotive Prototyping**

**Introduction**

In the automotive industry, prototyping is a critical step in the design and development process of new vehicles. Prototyping allows engineers and designers to test out ideas, make improvements, and ultimately create a product that meets the needs of customers. One of the key technologies used in automotive prototyping is CNC machining. CNC machining, or computer numerical control machining, is a process where a computer program controls the movement of tools to create precise and complex shapes. In this article, we will explore the role of CNC machining in automotive prototyping and how it has revolutionized the way cars are designed and developed.

**The Basics of CNC Machining**

CNC machining is a manufacturing process that utilizes computer-controlled machines to create parts and products from various materials such as plastics, metals, and composites. The process starts with a CAD (computer-aided design) model of the part that needs to be created. The CAD model is then converted into a set of instructions that the CNC machine follows to cut, drill, and shape the material into the desired shape. CNC machining is highly accurate and can produce complex parts with tight tolerances that are difficult to achieve using traditional machining methods.

One of the key advantages of CNC machining is its ability to produce parts consistently and quickly. Once the program is set up, the CNC machine can run continuously, producing identical parts with minimal human intervention. This makes CNC machining ideal for prototyping, where multiple iterations of a design need to be created and tested. Additionally, CNC machining is versatile and can work with a wide range of materials, allowing designers to create prototypes that closely resemble the final product in terms of look and feel.

**The Evolution of CNC Machining in Automotive Prototyping**

CNC machining has been used in automotive prototyping for decades, but recent advancements in technology have made the process even more efficient and cost-effective. In the past, automotive prototypes were often made by hand, using techniques such as clay modeling or foam cutting. While these methods were effective, they were time-consuming and limited in terms of precision and detail.

With the advent of CNC machining, automotive prototypes can now be created with unprecedented accuracy and speed. CNC machines can produce parts with intricate shapes and contours that would be impossible to achieve by hand. This has allowed automotive designers to create more realistic prototypes that accurately reflect the final product. Additionally, CNC machining is highly repeatable, meaning that multiple copies of a prototype can be created quickly and easily.

**The Benefits of Using CNC Machining in Automotive Prototyping**

There are several key benefits to using CNC machining in automotive prototyping. One of the main advantages is the ability to create prototypes quickly and cost-effectively. Traditional prototyping methods can be time-consuming and expensive, especially when multiple iterations of a design are required. With CNC machining, designers can make changes to a design on the fly and see the results almost immediately. This iterative process allows for faster development cycles and ultimately leads to better, more refined designs.

Another benefit of CNC machining in automotive prototyping is the ability to create highly accurate and detailed prototypes. CNC machines can produce parts with tight tolerances and complex geometries that are difficult or impossible to achieve with traditional machining methods. This level of precision is crucial in the automotive industry, where components need to fit together perfectly and perform flawlessly. CNC machining allows designers to create prototypes that are not only visually appealing but also functional and ready for real-world testing.

**Case Studies: How CNC Machining is Used in Automotive Prototyping**

To better understand how CNC machining is used in automotive prototyping, let's look at a few case studies of major automakers and their use of this technology.

One example is Tesla, the electric car manufacturer known for its innovative designs and cutting-edge technology. Tesla uses CNC machining extensively in the prototyping phase of new vehicle development. By quickly iterating on designs and creating high-quality prototypes, Tesla is able to speed up the development process and bring new vehicles to market faster.

Another example is BMW, a luxury car manufacturer that has been at the forefront of automotive design for decades. BMW uses CNC machining to create prototypes of new car components, such as interior panels and exterior body panels. By using CNC machining, BMW is able to create prototypes that are highly detailed and accurately represent the final product. This allows BMW to test out new designs and make improvements before going into full production.

**Conclusion**

Overall, CNC machining plays a critical role in the automotive prototyping process. By utilizing this advanced technology, designers and engineers can create highly accurate and detailed prototypes that closely mirror the final product. CNC machining is a versatile and cost-effective solution that has revolutionized the way cars are designed and developed. As technology continues to advance, we can expect to see even more innovations in CNC machining and its application in automotive prototyping.

The Impact of CNC Machining on Automotive Part Prototyping

With the advancement of technology, the automotive industry has seen a significant shift in how parts are prototyped. Traditional methods of prototyping, such as manual machining or injection molding, are being phased out in favor of more advanced techniques like CNC (Computer Numerical Control) machining. CNC machining offers numerous benefits for automotive part prototyping, including increased accuracy, faster turnaround times, and cost-effectiveness. In this article, we will explore how CNC machining is shaping the future of automotive part prototyping.

Understanding CNC Machining

CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools. The CNC machine works based on coded instructions programmed into its computer. These instructions dictate the movement and operation of the machinery, allowing for precise and intricate cuts to be made on materials such as metal, plastic, or wood. CNC machining has revolutionized the manufacturing industry by offering unmatched precision and repeatability in part production.

One of the key advantages of CNC machining is its ability to produce complex geometries that would be difficult or impossible to achieve using traditional machining methods. This makes CNC machining an ideal choice for prototyping automotive parts that have intricate designs and tight tolerances. Additionally, CNC machines can operate continuously without human intervention, leading to faster production times and increased efficiency.

The Benefits of CNC Machining for Automotive Part Prototyping

When it comes to automotive part prototyping, CNC machining offers several key benefits that set it apart from traditional methods. One of the most significant advantages of CNC machining is its precision and accuracy. CNC machines can achieve tolerances as low as 0.001 inches, ensuring that each part produced is an exact replica of the design specifications. This level of precision is crucial in the automotive industry, where even the smallest deviation can lead to performance issues or safety concerns.

Another benefit of CNC machining for automotive part prototyping is its versatility. CNC machines can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites. This versatility allows automotive manufacturers to test different materials and designs during the prototyping phase, helping them identify the best options for production. Additionally, CNC machining is a cost-effective solution for prototyping, as it eliminates the need for expensive tooling and reduces material waste.

Enhancing Prototyping Speed with CNC Machining

Speed is a critical factor in automotive part prototyping, as manufacturers strive to bring new products to market quickly and efficiently. CNC machining excels in this area by offering fast turnaround times for part production. Once a design is programmed into the CNC machine, it can begin producing parts immediately, without the need for manual setup or adjustments. This rapid production cycle allows automotive manufacturers to iterate on designs quickly and make adjustments based on real-world testing and feedback.

In traditional machining processes, prototyping a new automotive part can take weeks or even months to complete. With CNC machining, this timeline is dramatically reduced, with parts being produced in a matter of days. This increased speed not only accelerates the prototyping phase but also allows manufacturers to bring products to market faster, gaining a competitive edge in the automotive industry. By leveraging CNC machining for automotive part prototyping, manufacturers can streamline their development processes and respond more effectively to changing market demands.

Improving Efficiency and Sustainability in Automotive Part Prototyping

Efficiency and sustainability are becoming top priorities for automotive manufacturers as they seek to reduce waste and minimize their environmental impact. CNC machining plays a key role in improving efficiency and sustainability in automotive part prototyping by optimizing material usage and reducing the need for additional processing steps. CNC machines are programmed to make precise cuts that minimize material waste, ensuring that each part is produced with maximum efficiency.

Furthermore, CNC machining eliminates the need for secondary operations such as deburring or finishing, which are common in traditional machining processes. This not only saves time but also reduces the overall energy consumption and carbon footprint of part production. By streamlining the prototyping process and minimizing waste, CNC machining allows automotive manufacturers to create parts more sustainably and responsibly.

Conclusion

In conclusion, CNC machining is revolutionizing the way automotive parts are prototyped, offering unmatched precision, efficiency, and sustainability. By leveraging CNC technology, automotive manufacturers can produce complex parts with ease, accelerate their prototyping timelines, and reduce waste in the production process. As the automotive industry continues to evolve, CNC machining will play an increasingly vital role in shaping the future of automotive part prototyping. By embracing CNC technology and its numerous benefits, manufacturers can stay ahead of the curve and drive innovation in the ever-changing automotive landscape.

Engaging introduction:

Managing inventory in spare parts manufacturing, especially in the CNC machining industry, can be a challenging task. With the need to keep track of various components, materials, and tools, having a customized approach to inventory management is essential for efficiency and cost-effectiveness. In this article, we will explore the importance of customized inventory management in CNC machining for spare parts manufacturing and how it can benefit businesses in terms of productivity and profitability.

Maximizing Efficiency with Customized Inventory Management

In the world of CNC machining for spare parts manufacturing, efficiency is key to staying competitive and meeting customer demands. Customized inventory management systems can help companies optimize their operations by ensuring that the right parts and tools are always available when needed. By accurately tracking inventory levels and usage patterns, businesses can reduce lead times, minimize stockouts, and avoid excess inventory costs.

Implementing a customized inventory management system involves identifying the specific needs and requirements of the CNC machining process. This includes categorizing parts and tools based on usage frequency, criticality, and lead time, as well as setting appropriate reorder points and safety stock levels. With a tailored approach to inventory management, businesses can streamline their operations, reduce manual errors, and ultimately improve overall efficiency in spare parts manufacturing.

Enhancing Accuracy and Traceability

Accuracy and traceability are crucial aspects of inventory management in CNC machining for spare parts manufacturing. By customizing inventory management systems, businesses can enhance the accuracy of their inventory data and establish traceability throughout the production process. This includes implementing barcode scanning, RFID technology, or other automated tracking systems to ensure that parts and tools are correctly identified, located, and accounted for at all times.

With a customized approach to inventory management, businesses can minimize the risk of errors, discrepancies, and lost inventory items. By implementing strict inventory control measures and real-time tracking capabilities, companies can improve the accuracy of order fulfillment, reduce the likelihood of stockouts, and enhance overall traceability in spare parts manufacturing. This, in turn, can lead to improved quality control, customer satisfaction, and regulatory compliance.

Optimizing Cost Control and Inventory Valuation

Cost control and inventory valuation are critical considerations for businesses in the CNC machining industry, especially when it comes to spare parts manufacturing. Customized inventory management systems can help companies optimize their costs, minimize excess inventory, and improve inventory valuation accuracy. By implementing dynamic pricing models, demand forecasting algorithms, and inventory optimization techniques, businesses can reduce carrying costs, prevent stock obsolescence, and maximize profitability.

With a customized inventory management system, businesses can analyze their inventory data in real-time, identify cost-saving opportunities, and make informed decisions about inventory replenishment and procurement. By optimizing cost control and inventory valuation, companies can improve their financial performance, strengthen cash flow management, and enhance their competitive position in the market. This strategic approach to inventory management can help businesses achieve sustainable growth and profitability in the long run.

Streamlining Supply Chain Management and Vendor Relationships

Supply chain management and vendor relationships play a crucial role in the success of spare parts manufacturing businesses in the CNC machining industry. Customized inventory management systems can help companies streamline their supply chain processes, improve vendor collaboration, and enhance communication with key suppliers. By integrating inventory data with forecasting models, production schedules, and supplier portals, businesses can achieve greater visibility into their supply chain and make more informed decisions about inventory procurement and replenishment.

Moreover, with a customized approach to inventory management, businesses can strengthen their vendor relationships by establishing clear communication channels, setting performance metrics, and collaborating on inventory planning and optimization. By working closely with vendors and suppliers, companies can reduce lead times, manage supply chain risks, and improve overall operational efficiency in spare parts manufacturing. This strategic alignment of inventory management with supply chain management can lead to cost savings, process improvements, and competitive advantages in the market.

Embracing Digital Transformation and Industry 4.0 Technologies

In the era of digital transformation and Industry 4.0, businesses in the CNC machining industry are increasingly adopting advanced technologies to enhance their operations and improve their competitive edge. Customized inventory management systems can leverage digital tools, automation solutions, and data analytics to optimize inventory control, streamline processes, and drive continuous improvement in spare parts manufacturing. By embracing Industry 4.0 technologies such as IoT devices, cloud computing, and artificial intelligence, companies can achieve real-time visibility into their inventory, make data-driven decisions, and adapt to changing market conditions quickly.

With a customized approach to inventory management, businesses can future-proof their operations, increase agility, and capitalize on emerging opportunities in the CNC machining industry. By integrating digital technologies into their inventory management systems, companies can enhance operational efficiency, reduce costs, and improve decision-making capabilities. This can result in improved productivity, customer satisfaction, and profitability for spare parts manufacturing businesses in the long term.

Summary:

In conclusion, customized inventory management plays a vital role in the success of spare parts manufacturing businesses in the CNC machining industry. By optimizing efficiency, enhancing accuracy and traceability, controlling costs, streamlining supply chain management, and embracing digital transformation, companies can achieve operational excellence, improve customer satisfaction, and drive sustainable growth. With a tailored approach to inventory management, businesses can overcome challenges, capitalize on opportunities, and stay ahead of the competition in the ever-evolving landscape of spare parts manufacturing. By investing in customized inventory management solutions, companies can unlock their full potential, maximize their profitability, and achieve long-term success in the CNC machining industry.

China CNC Interpretation of trade policy for the export of processed parts

In today's global economy, trade policies play a significant role in determining the success of businesses involved in international trade. For China, as a major player in the manufacturing industry, understanding trade policies related to the export of processed parts is crucial for its continued growth and competitiveness in the global market. In this article, we will delve into the interpretation of trade policies for the export of processed parts by China CNC, a leading manufacturer in the country.

The importance of trade policies for export

Trade policies are rules and regulations that countries put in place to govern their international trade activities. These policies can have a significant impact on the export of processed parts, as they can affect factors such as tariffs, quotas, and licensing requirements. For China CNC, understanding and complying with these trade policies is essential to ensure the smooth export of its processed parts to international markets.

One key aspect of trade policies for export is tariffs. Tariffs are taxes imposed on imported goods by the importing country's government. They can significantly impact the competitiveness of a country's exports, as higher tariffs can make exported goods more expensive in foreign markets. For China CNC, staying updated on the tariffs imposed by different countries on processed parts is crucial to pricing its products competitively and maximizing its export potential.

Another important aspect of trade policies for export is licensing requirements. Some countries require exporters to obtain licenses or permits before they can export certain goods. These requirements can vary depending on the type of product being exported and the destination country. For China CNC, ensuring compliance with licensing requirements is crucial to avoid any delays or disruptions in its export operations.

Impact of trade policies on China CNC's export business

The export of processed parts is a significant part of China CNC's business, as it relies on international markets for a large portion of its sales. As such, trade policies related to the export of processed parts can have a direct impact on the company's bottom line.

One way in which trade policies can impact China CNC's export business is through changes in tariffs. If a key export market imposes higher tariffs on processed parts, China CNC may need to adjust its pricing strategy to remain competitive. This could potentially lead to lower profit margins for the company, especially if it is unable to pass on the full cost of the tariffs to its customers.

Additionally, licensing requirements can also pose challenges for China CNC's export business. If the company fails to obtain the necessary licenses or permits for exporting its processed parts, it could face delays in fulfilling orders or even legal consequences. This could damage China CNC's reputation in the market and result in the loss of valuable business opportunities.

Strategies for navigating trade policies in the export of processed parts

To navigate the complexities of trade policies related to the export of processed parts, China CNC employs a variety of strategies to ensure compliance and mitigate risks. One such strategy is to stay informed about changes in trade policies that may affect its export business. By closely monitoring developments in key export markets and seeking guidance from trade experts, China CNC can proactively adapt its export strategy to minimize potential disruptions.

Another strategy employed by China CNC is to diversify its export markets. By expanding its presence in multiple countries, the company can spread out its risk and reduce its dependence on any single market. This approach also allows China CNC to take advantage of different trade policies and market conditions in each country, maximizing its export potential.

In addition to staying informed and diversifying its export markets, China CNC also invests in building strong relationships with partners and stakeholders involved in its export operations. By establishing trust and open communication with suppliers, logistics providers, and customers, China CNC can streamline its export processes and resolve any potential compliance issues more effectively.

Challenges and opportunities in navigating trade policies for export

While navigating trade policies for the export of processed parts can present challenges for China CNC, it also offers opportunities for the company to grow and expand its global reach. One of the main challenges facing China CNC is the constantly evolving nature of trade policies, which can make it difficult to predict future changes and adapt its export strategy accordingly.

Another challenge for China CNC is the risk of trade disputes between countries, which can result in retaliatory tariffs or other trade barriers. These disputes can disrupt China CNC's export operations and negatively impact its business relationships with key trading partners. To mitigate these risks, China CNC closely monitors geopolitical developments and seeks to diversify its supply chain to reduce its exposure to potential trade disputes.

Despite these challenges, navigating trade policies for export also presents opportunities for China CNC to differentiate itself in the global market and expand its customer base. By demonstrating a strong commitment to compliance and quality, China CNC can build trust with international customers and position itself as a reliable supplier of processed parts. Additionally, by staying ahead of emerging trends in the manufacturing industry, such as the shift towards sustainable and environmentally friendly products, China CNC can attract new customers and drive growth in its export business.

Conclusion

In conclusion, trade policies play a crucial role in shaping China CNC's export strategy for processed parts. By understanding and navigating the complexities of trade policies related to tariffs, licensing requirements, and other factors, China CNC can maximize its export potential and maintain its competitiveness in the global market. While challenges such as evolving trade policies and trade disputes pose risks to China CNC's export business, they also present opportunities for the company to differentiate itself and drive growth. By employing strategies such as staying informed, diversifying export markets, and building strong relationships with partners, China CNC can successfully navigate trade policies for export and achieve its long-term business objectives.

Stainless steel is a popular material choice for many high-performance parts due to its strength, durability, and resistance to corrosion. When it comes to creating these parts, CNC machining is often the preferred method due to its precision, versatility, and ability to produce complex shapes with tight tolerances. In this article, we will explore why CNC machining is the best choice for manufacturing high-performance stainless steel parts.

Superior Precision and Accuracy

CNC machining is known for its exceptional precision and accuracy, making it the ideal choice for creating high-performance stainless steel parts. The computer-controlled nature of CNC machines allows for extremely tight tolerances to be achieved, ensuring that each part is consistently produced to the exact specifications required. This precision is crucial for parts that need to fit together seamlessly or function with minimal clearance, making CNC machining the go-to method for many industries.

In addition to precision, CNC machining offers unmatched accuracy when it comes to creating complex shapes and intricate details. With the ability to program the machine to follow precise paths and cutting depths, CNC machining can produce parts with intricate geometries that would be nearly impossible to achieve with traditional manufacturing methods. This level of accuracy is essential for high-performance parts that require intricate features or high levels of detail.

Wide Range of Stainless Steel Options

Stainless steel is available in a wide range of grades, each offering unique properties that make them suitable for different applications. Whether you need a stainless steel part with high strength, excellent corrosion resistance, or superior machinability, there is a grade of stainless steel that will meet your requirements. CNC machining is capable of working with a variety of stainless steel grades, allowing for the production of high-performance parts that are tailored to specific needs.

Some common stainless steel grades used in high-performance parts include 304, 316, and 17-4 PH. 304 stainless steel is known for its excellent corrosion resistance and ease of fabrication, making it a popular choice for a wide range of applications. 316 stainless steel offers even greater corrosion resistance and is often used in demanding environments such as marine or chemical processing. 17-4 PH stainless steel combines high strength and hardness with good corrosion resistance, making it an ideal choice for parts that require both toughness and durability.

Cost-Effective Production

Contrary to popular belief, CNC machining can be a cost-effective option for producing high-performance stainless steel parts. While the initial investment in CNC equipment and programming may be higher than traditional manufacturing methods, the long-term benefits of CNC machining often outweigh the upfront costs. By eliminating the need for costly tooling changes, reducing scrap material, and minimizing human error, CNC machining can lead to significant cost savings over time.

Additionally, the speed and efficiency of CNC machining can help to reduce lead times and increase overall productivity, further contributing to cost savings. With the ability to run multiple operations simultaneously and produce parts with minimal human intervention, CNC machining offers a cost-effective solution for high-volume production of stainless steel parts. Overall, the combination of precision, accuracy, and efficiency makes CNC machining a highly cost-effective option for creating high-performance stainless steel parts.

Improved Quality and Consistency

Quality control is a critical aspect of manufacturing high-performance parts, especially when working with materials as demanding as stainless steel. CNC machining offers improved quality and consistency compared to traditional manufacturing methods, thanks to its computer-controlled operation and ability to maintain tight tolerances. With CNC machining, each part is produced with the same level of precision and accuracy, ensuring uniformity and consistency across all pieces.

In addition to improved quality, CNC machining also allows for greater control over the manufacturing process, making it easier to identify and rectify any potential issues before they become costly problems. By using simulation software to test and refine the machining program before production begins, CNC machining helps to minimize the risk of errors and ensure that each part meets the required specifications. This level of quality control is essential for producing high-performance stainless steel parts that meet the highest standards of excellence.

Enhanced Surface Finish and Aesthetics

One often-overlooked benefit of CNC machining for high-performance stainless steel parts is the ability to achieve superior surface finishes and aesthetics. CNC machining can produce parts with a smooth, polished surface that is free from imperfections such as burrs, tool marks, or scratches, resulting in a clean and professional appearance. This is especially important for parts that will be visible or used in high-end applications where aesthetics are crucial.

Furthermore, CNC machining offers the flexibility to create custom surface finishes through various methods such as polishing, etching, or brushing, allowing for a high degree of customization to meet specific design requirements. Whether you need a mirror-like finish for a decorative part or a textured finish for improved grip, CNC machining can deliver the desired surface quality with precision and consistency. The ability to achieve enhanced surface finishes and aesthetics makes CNC machining the ideal choice for creating high-performance stainless steel parts that not only perform well but look great too.

In conclusion, CNC machining is the ideal choice for manufacturing high-performance stainless steel parts due to its superior precision, wide range of stainless steel options, cost-effective production, improved quality and consistency, and enhanced surface finish and aesthetics. Whether you need parts with tight tolerances, complex geometries, or pristine surface finishes, CNC machining can deliver the results you need with unmatched accuracy and efficiency. By choosing CNC machining for your stainless steel parts, you can ensure that your products meet the highest standards of performance, quality, and durability.

Contact: Ada Li

Tel: +86 17722440307

WhatsApp: +86 17722440307

E-mail: vicky@honscn.com

Add: 4F, No. 41 Huangdang Road, Luowuwei Industrial, Dalang Street, Longhua, Shenzhen, 518109, China