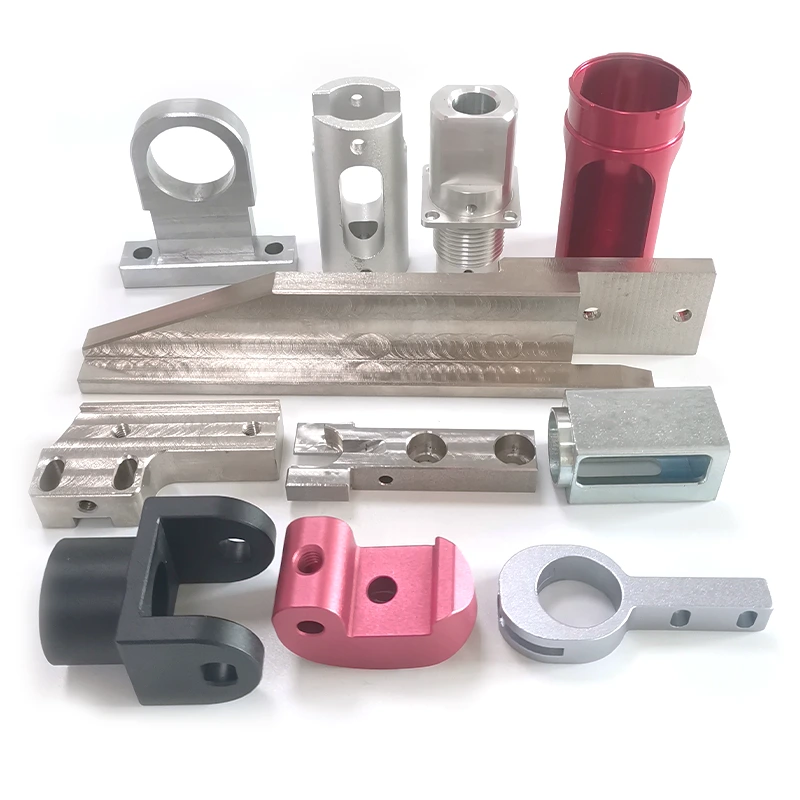

Customized CNC turning and milling parts | Multi-axis precision machining | ±0.003mm tolerance control

High Precision: CNC turning and milling parts are manufactured with high accuracy, meeting strict tolerance requirements.

Versatility: Suitable for various materials (metals, plastics, composites) and industries (automotive, aerospace, electronics, etc.).

Complex Shapes: Capable of producing complex and intricate designs.

Functions and Roles

Automotive Industry: Used for engine components, brackets, and other structural parts.

Aerospace Industry: Critical for manufacturing aircraft components, such as wing parts and engine mounts.

Electronics Industry: Used to create casings, brackets, and other components for electronic devices.

Medical Industry: Essential for producing surgical instruments and medical device parts.

Industrial Equipment: Used in the production of machinery and tooling components.

Advantages

High Precision: Ensures accurate and consistent part dimensions.

Versatility: Can work with a wide range of materials and produce various part types.

Complex Designs: Enables the creation of intricate and detailed parts.

Efficiency: Fast and automated production process.

Quality Consistency: Repeatable and consistent part quality.

Cost-Effective: Reduces waste and labor costs.

Customized CNC turning and milling parts

The turning and milling integrated processing parts are designed for highly complex transmission systems, fluid control components and precision instruments. They support 5-axis synchronous turning and milling, and can complete the precision molding of complex features such as threads, curved surfaces, keyways, etc. It can achieve a surface finish of Ra0.4μm, and provide 20 surface treatment solutions such as hard anodizing and chemical nickel plating to meet the strict requirements of medical, aviation and industrial automation fields for geometric accuracy and functional integration.

ISO 9001 certification | 72-hour rapid proofing | Fully compatible with aluminum/stainless steel/titanium alloy/engineering plastics

Product Details

Product Advantages

Technical advantages

Process Advantages

Service Advantages

Application

FAQ

If you have any questions, please feel free to contact us at ada@honscn.com or by phone at +86 17722440307