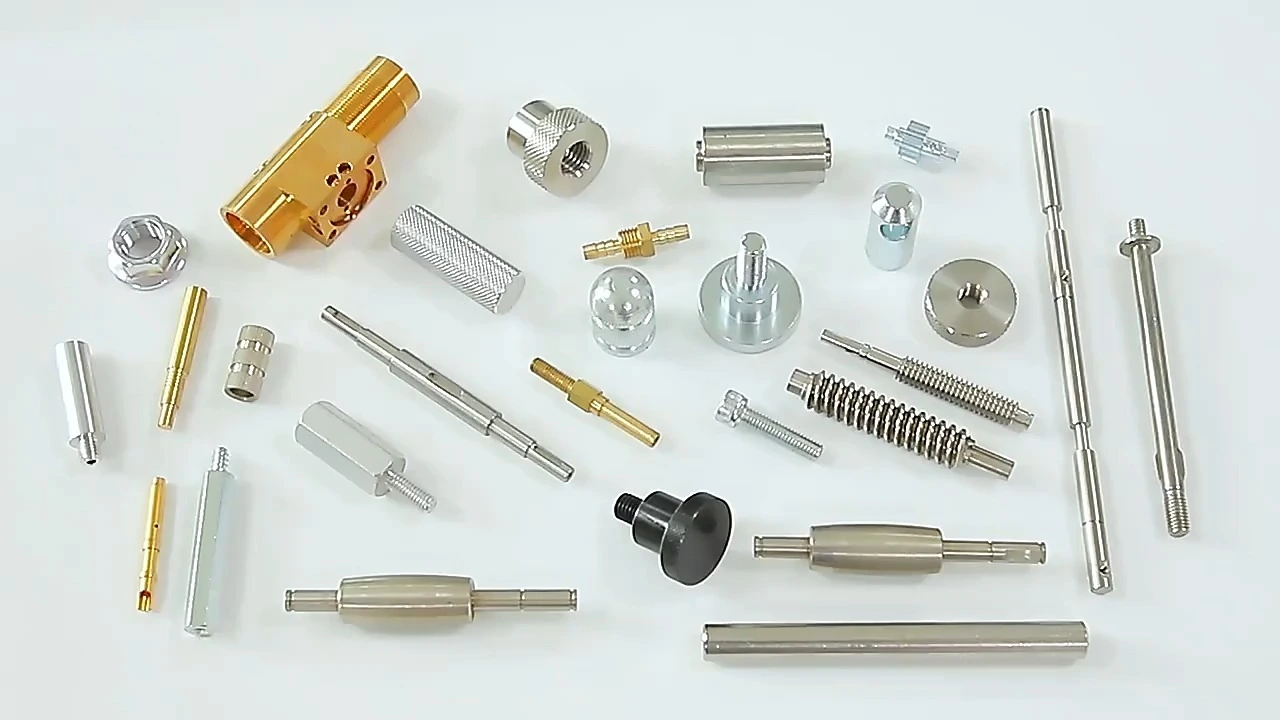

Customized OEM CNC Turning Machining Precision Metal Shaft and Pin

Ventaja : Accepts bespoke designs (drawings/samples) for unique specifications.

Details :Supports OEM/ODM manufacturing (private labeling).

Handles non-standard parts with tailored dimensions/materials.

High-Precision CNC Machining

Ventaja : CNC turning ensures tight tolerances and complex geometries.

Details : Tolerance : As tight as ±0.005mm (material-dependent)

Equipment : Multi-axis CNC lathes (e.g., Swiss-type).

Material & Finishing Options

Ventaja

: Versatile metal choices for diverse industrial needs.

Details

:

Materiales

: Stainless steel (303/304/316), carbon steel, aluminum, brass, titanium.

Surface treatments

: Plating, anodizing, passivation, polishing.

Product Focus (Shafts & Pins)

Ventaja

: Specialization in precision rotational components.

Details

:

Shafts

: Drive shafts, lead screws, spindles.

Pins

: Dowel pins, spring pins, roll pins.

High strength precision shaft pin

High-precision pins designed for electronics, automotive and aerospace fields are made of AISI 4140 alloy steel, 316 stainless steel and titanium alloy, and support customized sizes (diameter 1mm-50mm). Through heat treatment + surface coating process, the tensile strength is ≥1200MPa, meeting the durability and stability requirements under extreme working conditions.

Product Details

Product Advantages

Material properties

Process accuracy

Service Guarantee

Our advantage

Application

FAQ

If you have any questions, please feel free to contact us at ada@honscn.com or by phone at +86 17722440307